The Science

What is Neutral Buoyancy?

For cleanroom applications, particles which are Neutrally Buoyant are influenced only by air currents within the cleanroom or area being tested. Gravity and the particle cloud temperature and pressure do not influence their behavior during the testing.

Particle Settling Velocity

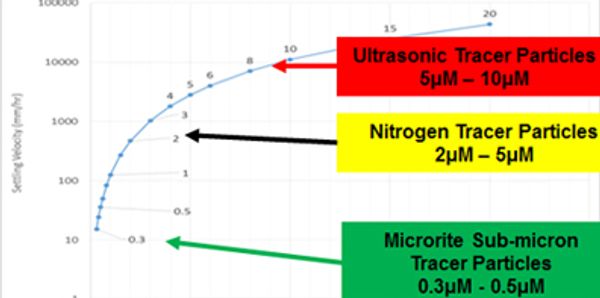

Microrite’s Tracer Particles have a Very Low Settling Velocity compared with Water CO2 or Nitrogen Based “Cleanroom Foggers”

Vapor Pressure

Water, CO2 or Nitrogen Based ”Cleanroom Foggers” produce a high vapor pressure particle cloud that evaporates rapidly under normal atmospheric conditions and condenses rapidly once the cloud reaches its saturation vapor pressure.

Metrology

Tracer Particle Generator (TPG-M1) Calibration

Air flow visualization tests are utilized to evaluate the contamination control effect of cleanroom air on controlling contamination in the process. Clean air particles are specified by their cleanroom class with each increasing class indicating a factor of 10 increase in particle levels. Good metrology practice requires an instrument’s accuracy and reproducibility be significantly better than the accuracy of the measurement (in this case the cleanroom class). For example, optical particle counters which are used to certify cleanroom classes by measuring actual particle levels are required by ISO-21501-4 to have a count accuracy of +-10% or a fraction of a cleanroom class.

The Microrite Trace Particle Generator utilizes a vaporizer to simulate smoke for air flow visualization studies. In order to be able to reproduce tests particle levels with a variability that is a fraction of a cleanroom class, each vaporizer is calibrated to confirm that the amount of fluid vaporized is +-10% of a standard value. In addition, an optical particle counter is utilized to check the particle size distribution of the vapor. The size distribution test confirms that 95% of the vapor particles are less than 1.0 micron to ensure neutral buoyancy and to simulate contamination particle sizes as closely as possible.

In summary the Tracer Particle Generator Calibration assures that the accuracy of the particle concentration and particle size distribution of the generated fog meet acceptable levels for visualizing the contamination control effect of cleanroom air over a range of classes.

References

Why are other Cleanroom Foggers Unsuitable for Testing Medical Product Cleanrooms?

Per CETA Certification Guide for Sterile Compounding Facilities CAG-003-2006 -13 Revised May 20, 2015 Section 13.5:

- Water based fog generators such as CO2 and liquid nitrogen create a fog that is heavier than air and do not always provide for an accurate representation of the actual air patterns.

- The smoke source should be as close to neutrally buoyant as possible. For example, when generating the fog in an area with no detectable airflow, it should not “fall out” or “drop”.

- Fog streams that are heavier than air may not detect updrafts and turbulence that are detected with a generally neutral buoyant detection stream.

Why Reference CETA?

Controlled Environment Testing Association (CETA)

The Controlled Environment Testing Association (CETA) is specifically referenced in USP 797 Section 5: Certification and Re-certification:

Before a compounding area is used to compound either Category 1 or 2 CSPs, it must be certified using procedures in the current Controlled Environment Testing Association (CETA) Certification Guide for Sterile Compounding Facilities or an equivalent guideline.

There's much to see here. So, take your time, look around, and learn all there is to know about us. Please take a moment to drop us a line if you have any questions.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience.